Recently, Washoku Lovers was invited to visit the factory where Maruko Gyoza and also ramen noodles are made! Watching the foods be produced was extremely interesting, so let me break it down for you:

Gyoza

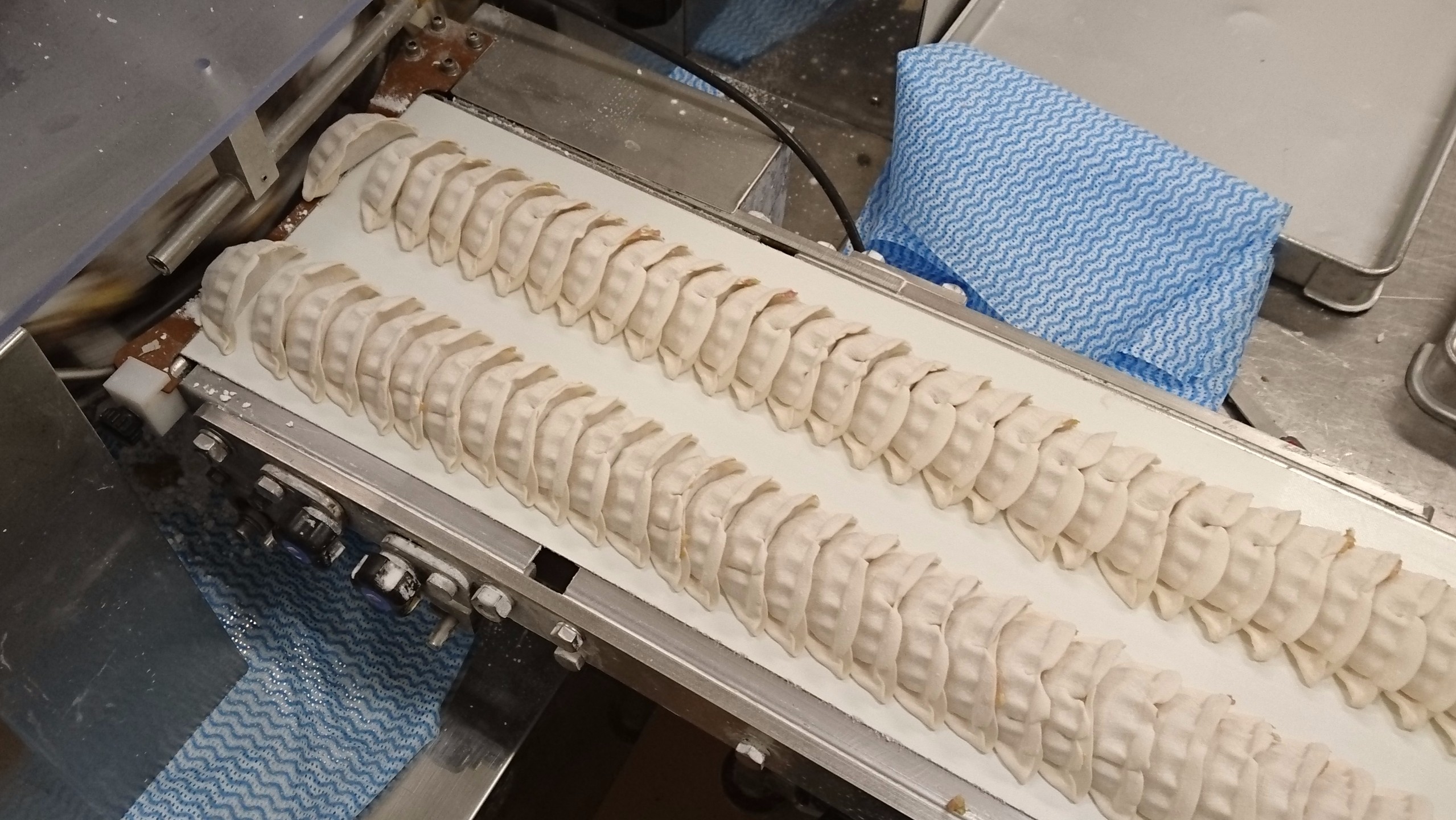

The dumpling wrappers are a simple flour-water mixture (but the flour itself is a secret!) that’s churned in a machine and then transferred to another machine. The second machine is where all the action is – the mixture is combined into the smooth consistence we all know, and then put on a conveyor belt like contraption that rolls the dough flat. At the end of the belt, circles are punched out and fall onto a rotating piece of machinery. The flat wrapper moves around, has the meat filling pushed on it, moves around again, and is finally folded and pushed out.

Each machine is capable of churning out 8000 dumplings per hour! It’s quite mesmerising to watch the repetitive meat filling and folding.

After assembly, each individual gyoza is put through quality testing. The first stage is a working checking that they all look uniform and are properly holding together. Then they’re packed onto trays and frozen. The freezer is -18°C and as soon as you walk in, you’re cold to your bones. I was definitely happy to be out of that part!

Before being packed into bags for sale, the gyoza are tested again. This time for metal contaminants. The machine that scans the gyoza is highly sensitive in order to detect trace amounts of contaminants. Due to high quality, Australian ingredients, any contamination is more likely to come from the equipment or workers dropping something in. Luckily this isn’t an issue at all, and if anything is ever detected, all machines and ingredients are thoroughly inspected.

In Japanese, NG refers to “no good”, it’s an effective way to get the message across!

Ramen

The ramen process starts much the same as gyoza, with water and flour combined, but for ramen they also add oil which gives it its yellow colour. It’s then flattened and rolled up and transferred to another machine. Once set up, the roll of dough is fed through four presses, which thin the dough out. The thickness can be changed so the machine can make different ramen sizes, or even made completely different noodles like udon which are much thicker.

In the last stage, the dough is cut into strips, finally becoming noodles. An attachment can be put on the cutting blade to make wavy noodles, or removed for straight noodles. I was amazed by how simple the basics of making the ramen is, but also amazed by how complex the final product is and how much attention to detail goes in to getting it just right.

After the noodles look like noodles, they are cut into portion sizes. Rather being measured by weight, there is a timer on the machine which tells it when to cut the noodles. They’re then inspected and packaged.

Maruko Gyoza and Ramen can be found in the freezer section at selected retailers:

Miracle Supermarket Mandarin C – 61-65 Albert Ave, Chatswood NSW 2067

Maruyu Yumehiroba – 537-539 Kent St, Sydney NSW 2000

CITI SUPER – Lower Ground, 14 Wilmot St, Sydney NSW 2000

MIRACLE MACQUARIE – Shop 3508, Macquarie Centre. North Ryde, NSW 2113

New Yen Yen Top Ryde Super – Shop 25, 1 Lakeside Rd, Eastwood NSW 2122

Convenience Store Eight – 303 Pitt Street, Sydney NSW 2000